- Home

- About us

- Products

- Hot dipped Galvanized steel pipe(tube)

- ERW black steel pipe/tube

- ERW spiral welded pipe

- Pipe fitting

- API Steel Pipe(API 5CT)

- Structural section

- LSAW &SSAW steel pipe

- Seamless Steel Pipe(Tube)

- GI Steel Strip/Steel Coil(corrugated sheet)

- Galvanised Steel Pipe (Tube)

- Welded Steel Pipe (Tube)

- Pre Galvanised Steel Pipe (Tube)

- Square / rectangular hollow section

- Other Steel Products

- Scaffolding

- Faqs

- News

- Certificate

- Contact us

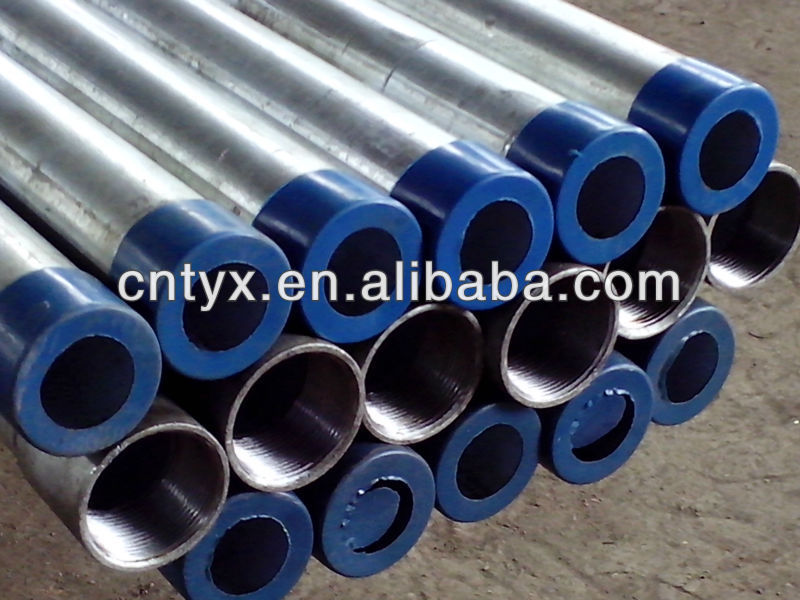

ASTM A53 galvanized steel pipe

- FOB Price

US $950.0020 - 40,000 metric ton

US $550.0040,001 - 999,999 metric ton

- group name

- TYT STEEL SCAFFOLDING

- Min Order

- 20 metric ton

- brand name

- TYTSTEEL

- Nearest port for product export

- TIANJIN XINGANG PORT, QINGDAO PORT, SHANGHAI PORT, NINGBO PORT

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, CIP, CPT, DDP, DDU

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Credit Card, Westem Union, Escrow

- update time

- Tue, 22 Apr 2014 14:14:01 GMT

Paramtents

Standard BS, GB, ASTM

Standard BS 1387, BS 1139, BS 4568, BS EN 39, GB/T 13793-1992, ASTM A106-2006

Grade 16Mn, A53-A369, ST35-ST52, Q195-Q345

Grade 16Mn, A53(A,B), St37, St52, St42, Q235, Q345, Q195, Q215

Thickness 1.2 - 15 mm

Section Shape Round

Outer Diameter 21.3 - 273.1 mm

Application Structure Pipe

Technique ERW

Certification ISO9001-2008

Surface Treatment Galvanized

Special Pipe Thick Wall Pipe

Standard BS, GB, ASTM

Grade 16Mn, GR.B, ST35-ST52, Q195-Q345B

Thickness 1.2-15mm

Surface Treatment Galvanized

Brand name TYSTEEL

Certification ISO9001-2008

other name hot dip galvanized steel pipe,ASTM A53 A galvanized steel pipe

relative name bs 1387 galvanized steel pipe

Packging & Delivery

-

Min Order20 metric ton

Briefing

1).Specification:1/2" to 10"

2).Grade:Q195/Q215/Q235/Q345/st33

Reliable manufacturer in Tianji

Detailed

ASTM A53 Galvanized steel pipe

| ASTM A53 SCHEDULE 40 GRADE A & B | |||||||||||||

| Outside Dia. Of Black iron pipe/hot dip Galvanized tube | Weight of Black iron /Hot dip Galvanized tube | ||||||||||||

| SIZE | Minimum | Maximum | Wall Thickness | Plain Ends | Secrewed & Socketed | Pieces | |||||||

| INCH | NB(mm) | INCHES | mm | Inches | mm | Inches | mm | lb./Ft. | Kg./Mtr. | lb./Ft. | Kg./Mtr. | per bundle | Factory standard |

| 1/2'' | 15 | 0.809 | 20.9 | 0.856 | 21.7 | 0.109 | 2.77 | 0.85 | 1.27 | 0.85 | 1.27 | 120 | 217 |

| 3/4'' | 20 | 1.020 | 26.3 | 1.070 | 27.1 | 0.113 | 2.87 | 1.13 | 1.69 | 1.13 | 1.69 | 84 | 169 |

| 1'' | 25 | 1.280 | 33.0 | 1.330 | 33.8 | 0.133 | 3.38 | 1.68 | 2.50 | 1.68 | 2.50 | 60 | 127 |

| 11/4'' | 32 | 1.630 | 41.8 | 1.680 | 42.6 | 0.140 | 3.56 | 2.27 | 3.39 | 2.28 | 3.40 | 42 | 91 |

| 11/2'' | 40 | 1.870 | 47.9 | 1.920 | 48.7 | 0.145 | 3.68 | 2.72 | 4.05 | 2.73 | 4.06 | 36 | 91 |

| 2'' | 50 | 2.350 | 59.7 | 2.400 | 60.9 | 0.154 | 3.91 | 3.65 | 5.44 | 3.68 | 5.46 | 26 | 37 |

| 21/2'' | 65 | 2.850 | 72.3 | 2.900 | 73.7 | 0.203 | 5.16 | 5.79 | 8.63 | 5.82 | 8.67 | 18 | 37 |

| 3'' | 80 | 3.460 | 88.0 | 3.530 | 89.8 | 0.216 | 5.49 | 7.58 | 11.29 | 7.62 | 11.35 | 14 | 37 |

| 31/2'' | 90 | 3.960 | 100.6 | 4.040 | 102.6 | 0.226 | 5.74 | 9.11 | 13.57 | 9.20 | 13.71 | 12 | 19 |

| 4'' | 100 | 4.450 | 113.2 | 4.540 | 115.4 | 0.237 | 6.02 | 10.79 | 16.07 | 10.89 | 16.20 | 10 | 19 |

| 5'' | 125 | 5.510 | 139.9 | 5.620 | 142.7 | 0.258 | 6.55 | 14.62 | 21.77 | 14.81 | 22.10 | 7 | 19 |

| 6'' | 150 | 6.560 | 166.6 | 6.690 | 169.98 | 0.280 | 7.11 | 18.97 | 28.26 | 19.18 | 28.60 | 7 | 19 |

1.TOLERANCE:

| |||||||||||||

| a)On Thickness: The minimum wall thickness at any point shall be not more than 12.5% under the nominalwall thickness specified. | |||||||||||||

| b)On Diameter:For NPS 11/2" & under at any point shall not vary more than +/- 0.4mm. For NPS 2" & above shall not vary more than +/-1% from the standard specified. | |||||||||||||

| c)On Weight: The weight of the pipe shall not vary by more than +/- 10% of the specified value. | |||||||||||||

2.ENDS:

| |||||||||||||

| a)11/2" and below size - End finish shall be at the option of manufacturer. Nominally square cut with theaxis of tube and free from excessive burrs. | |||||||||||||

| b)2" and above size - Bevelled with ends bevelled to an angle of 30 degrees +5/-0 measured from a line perpendicular to the axis of the pipe with a root face of 1.6mm +/-0.8mm. | |||||||||||||

3.INTERNAL DEBEADING: From size 2" & above internal beads can be completely removed.

| |||||||||||||

4.PROPERTIES:

a) Chemical = (Maximum) C - 0.30%, Mn - 1.20%, S - 0.045% & P - 0.050%, Cu-0.40%, Ni-0.40%, Cr-0.40%,Mo-0.15%, V-0.08%, (Cu+Ni+Cr+Mo+V = 1.0% max) | |||||||||||||

| b) Mechanical (Minimum) = UTS - 415 N/mm2, YS - 240 N/mm2 & %Elongation 19 to 25% . | |||||||||||||

| 5.BEND TEST (COLD): Applicable to tubes upto and including nominal size of 50mm. | |||||||||||||

a)When ordered for close coiling bend upto 180 degrees around a cylindrical mandrel, the Dia of which is 8 times the OD of pipe. | |||||||||||||

b)Bend upto 90 degree around a cylindrical mandrel, the dia of which is 12 times the OD of pipe .No cracks at any portion and no open in the weld. | |||||||||||||

| 7.LEAK TIGHTNESS TEST:a) Online NDT (Eddy current ) b) Hydro test at a pressure of 700 PSI to 2500 PSI | |||||||||||||

| 8.ZINC COATING: Average 550 Gm/M2, but one side should not be less than 490 Gm/M2. Free from bare spots,black spots,(GALVANIZING) rough,overcoating,peel off or any other surface defects. | |||||||||||||

| 9.THREADING: For 1/2" to 3/4" - 14 TPI, 1" to 2" - 11.5 TPI and 21/2" to 6" = 8 TPI.Check with standard ASTM ring and plug gauges. | |||||||||||||

| 10.MARKING: We can do online by stencilling as per this standard & as per customer needs at one meter interval. | |||||||||||||

| 11 PACKING:Hexagonal type. | |||||||||||||

| 12.MILL TEST CERTIFICATE: We can issue a MTC, certifying that the tubes supplied comply with this ASTM A 53 Standard. | |||||||||||||

key words: hot dip galvanized steel pipe , ASTM A53 A galvanized steel pipe , bs 1387 galvanized steel pipe ,pre galvanized steel pipe , pre galvanized steel tube , round tube, carbon steel pipe , conduit pipe, seamless steel pipe ,

Product Showcase